We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Parts On Demand

High Performance Plastics

Onyx

Material Overview

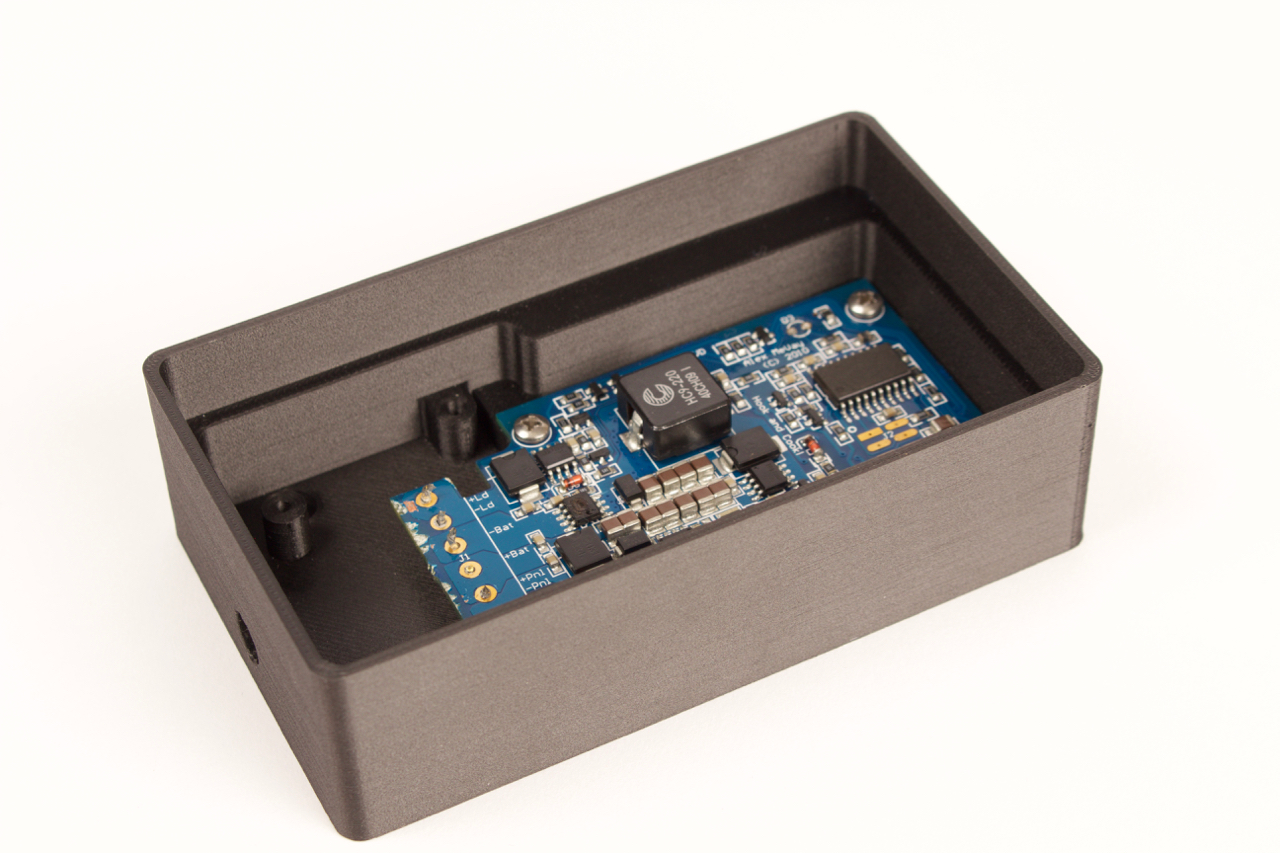

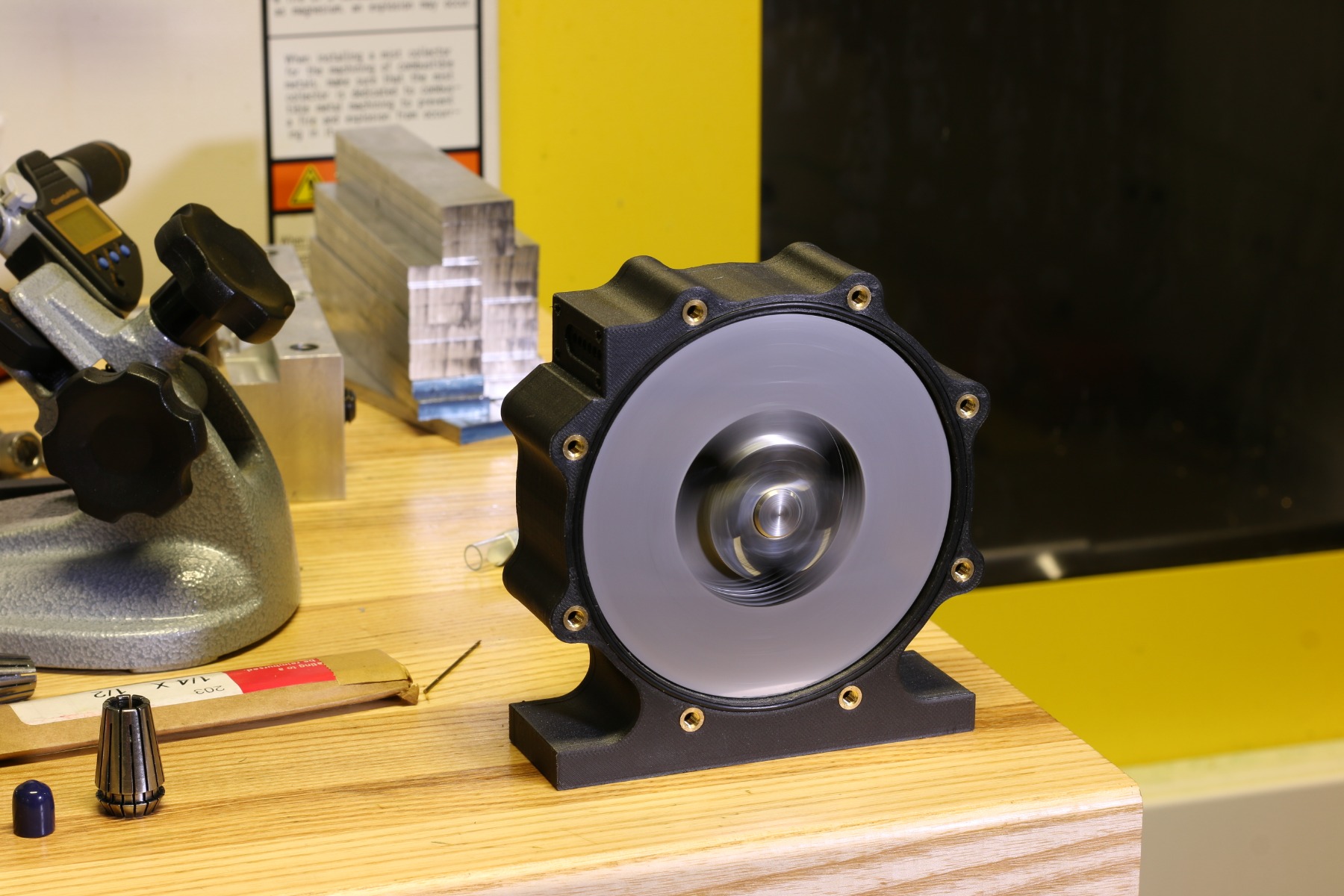

Onyx 3D material is a micro carbon fiber filled nylon that yields accurate parts with impeccable surface finish. Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts.

Common Applications

Plastic Part Replacement, Housings, Sensor Mounts and Cosmetic Prototypes

Key Material Properties

Durable and Strong

Excellent Chemical Resistance

High Heat Deflection Temp

Flexural Strength (MPA) 71

Tensile Strain at Break % 58

HDT at 0.4555 MPA 145°C

Maximum Part Size 330 x 270 x 200 mm (13 x 10.6 x 7.8 in)

Layer Thickness Options 50, 100, 125, 200, 250 Micron Layers

What is the 3D printing process for this material?

Onyx 3D is printed utilizing Markforged's FFF (Fused Filament Fabrication) 3D printing process. The Markforged FFF technology provides industry leading accuracy and reliability. Markforged industrial 3D printers offer strong parts with 50 μm repeatability and industry-leading surface finish.

Will there be support scarring on this part?

Since the Markforged 3D printer cannot extrude plastic into thin air without it collapsing, all parts of each layer must be connected to the layer below. Markforged FFF 3D printing technology utilizes peel away supports (made from the same material as the part) for any overhangs that require supports. Once the peel away supports are removed there will be support scarring on the part.

How long will it take before I receive my part in this material?

Production times vary depending on machine availability, but generally Onyx parts are printed and shipped within 1-2 business days.

What is the part accuracy and tolerances that this material can hold?

3D printing accuracy depends on a number of factors, including material, print settings, and part orientation. However, Markforged industrial 3D printers offer strong parts with 50 μm repeatability and industry-leading surface finish.

What are some of the specific design considerations when designing parts for this material?

When printing features that require high accuracy try to design or orient your part such that holes and other critical features lay flat on the print bed. Since the XY gantry is a unified motion system, printers produce far more accurate geometries on the XY (horizontal) than the XZ or YZ (vertical) planes. You can also reduce supports and overhangs Reduce supports and overhangs: Supports ensure that geometrically complex prints are successful; however, they also mar the supported surface and yield significantly less accurate features than sections that do not require support.

Upload A File To Get Started