We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Parts On Demand

High Performance Metals

Copper3D Parts Service

Material Overview

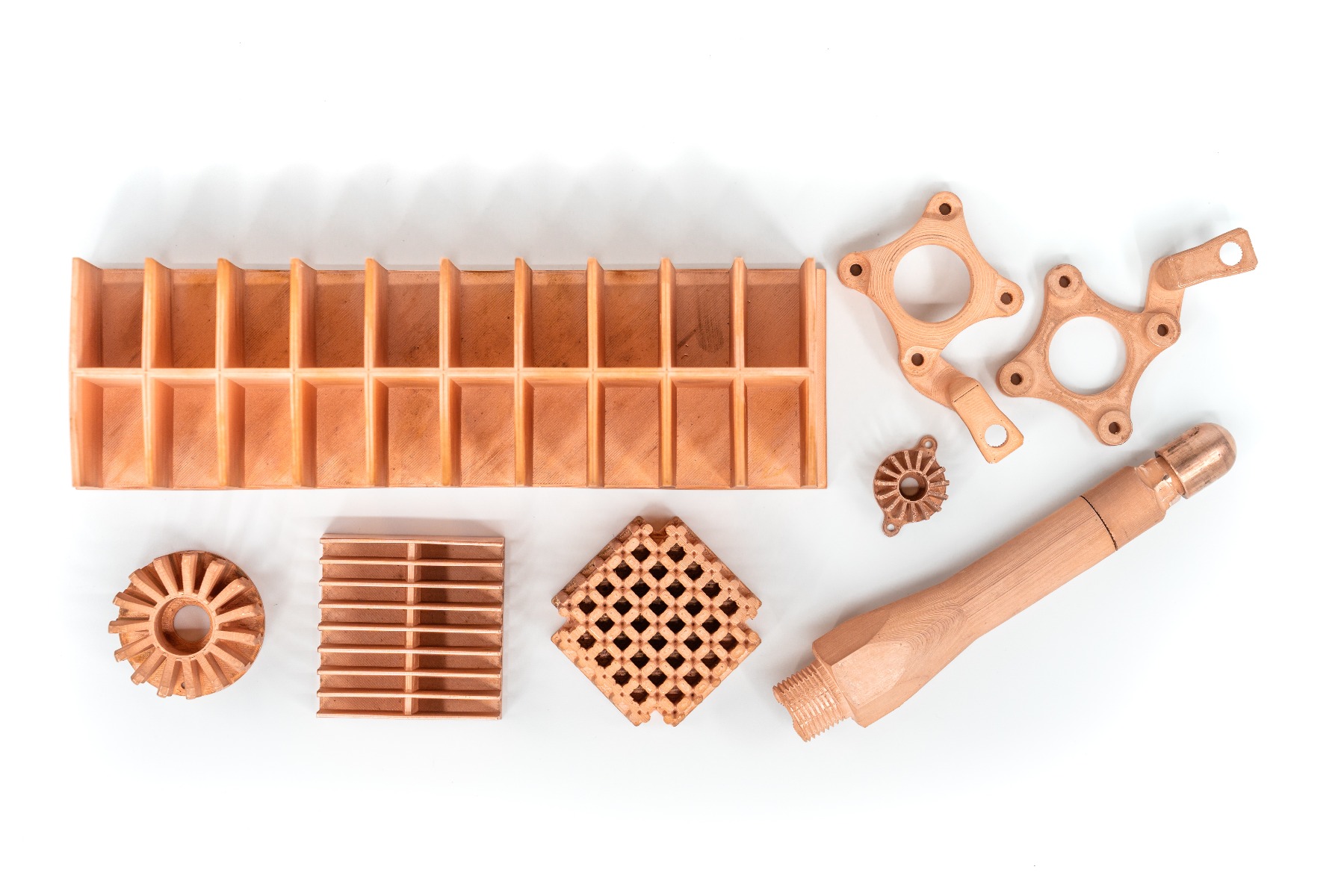

Copper 3D printing material from Markforged is unparalleled in its ability to conduct both heat and electricity. Markforged Copper possesses better conductivity characteristics than alloyed copper that can be printed on DMLS machines. Unlike conventional fabrication processes which are extremely labor intensive and expensive, Markforged Copper is extremely simple to 3D print.

Common Applications

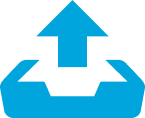

Welding Shanks, induction coils, heatsinks, bus bars, custom fittings, adapters and EDM electrodes

Key Material Properties

84% IACS Electrical Conductivity

350 W/mK Thermal Conductivity

Lightweight Honeycomb Infill

Maximum Part Size 300 x 220 x 180 mm (11.8 x 8.6 x 7 in)

Part Accuracy - Parts are printed to "near net shape" and can be post processed if needed

What part file formats are supported?

stl, stp, step, obj and wrl

What is the 3D printing process for this material?

Copper parts are 3D printed utilizing the Markforged Metal X 3D metal printer. By printing metal powder bound in a plastic matrix, Markforged has become the first company to eliminate the safety risks associated with traditional metal 3D printers. Once the Copper part has been printed it is “washed” in a washing station which removes some of the binder found in the printing filament. From the wash the part is fired in the sintering furnace where the last remaining binder is burned away and the metal part is fused together.

How long will it take before I receive my part in this material?

Production times vary depending on machine availability, but generally Copper 3D parts are printed and shipped within one to two weeks.

Upload A File To Get Started