We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Markforged X3 3D Printer

Product of Interest:

Markforged X3 3D Printer

SKU: F-PR-3004

3D Printing Process - Fused Filament Fabrication (FFF)

3D Printing Build Envelope - 330 mm x 270 mm x 200 mm

3D Printing Layer Resolution - 50 μm - 200 μm

X3 Printer Footprint - 584 mm x 483 mm x 914 mm (23 x 19 x 36 in)

Available 3D Printing Materials : Onyx

(See PDF's Tab for Markforged Material Data Sheet)

Markforged X3 3D Printer

The X3 merges industrial quality and build volume into a benchtop form factor, bringing FFF composite 3D printing to your manufacturing floor.

High-Strength Printing

The X3 brings two versatile, advanced, micro carbon fiber filled nylon materials to a precision-built FFF platform, delivering functional part after functional part.

Precise and Beautiful Parts

Print in a wide variety of print modes all optimized to yield quality parts — including 50 μm resolution, which delivers ultra-high-quality parts without visible layer lines.

Built to Last

Precision-machined hardware, advanced sensors, and unique software drive industry leading accuracy and reliability. Only Markforged industrial 3D printers offer micron-level laser scanning for closed-loop calibration, reliably yielding parts with 50 μm repeatability and industry-leading surface finish.

Simple FFF Process. Robust Parts.

3D Printing Process

Fused Filament Fabrication (FFF)

Printing Material

Composite Base Filaments

Build Envelope Size

330 mm x 270 mm x 200 mm (12.9 x 10.6 x 7.8 in)

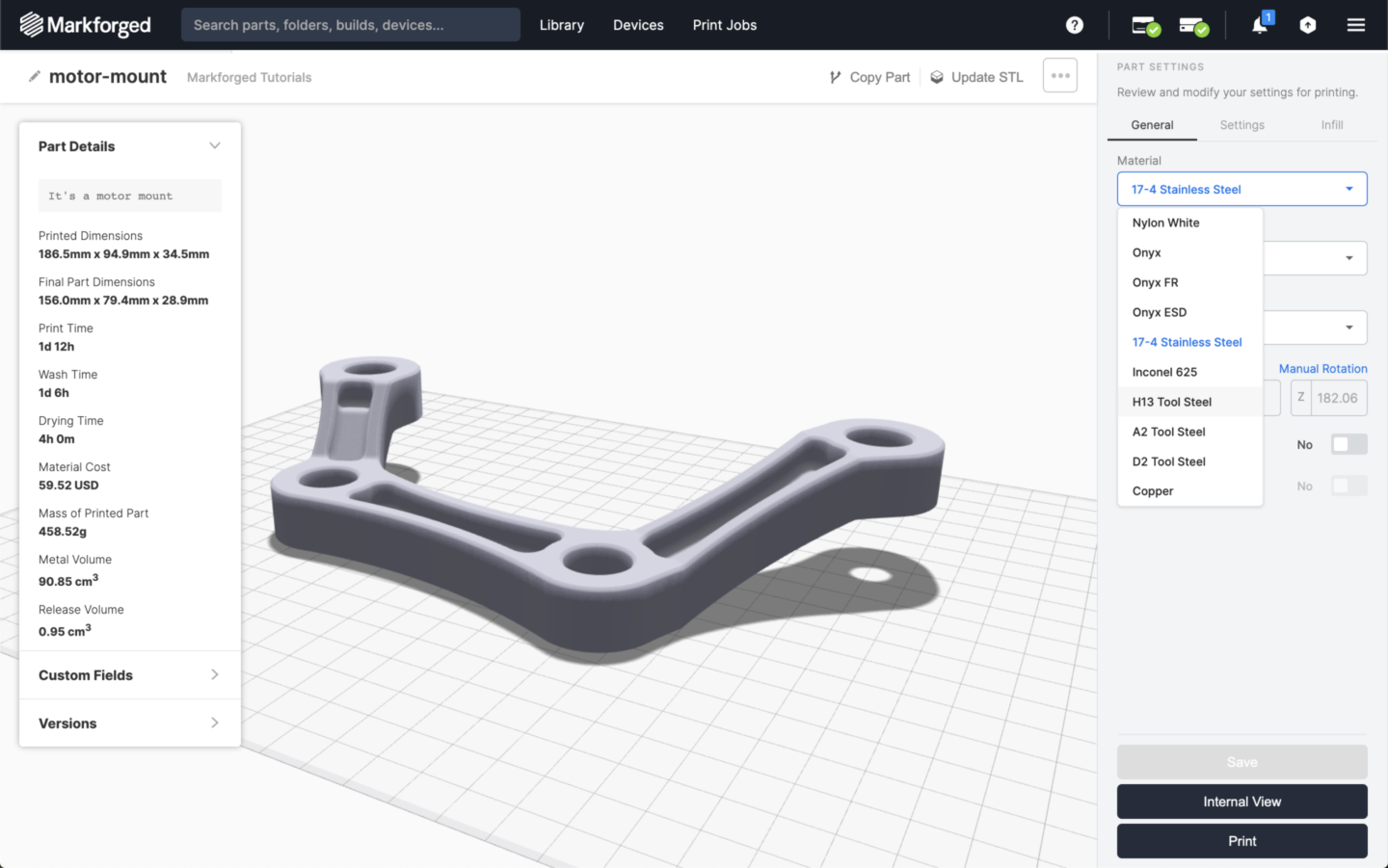

Onyx

Onyx FR

Onyx ESD

About the X3

The Markforged X3 industrial 3D printer combines precision-built hardware, advanced sensors, and best-in-class software to deliver accurate parts repeatably. It features a reinforced, precision-machined gantry and a precision ground print bed that can be removed and replaced with 10um repeatability. Each piece of hardware in the filament extrusion system — from the nozzles to the extruder hobs — is optimized to resist wear from micro carbon fiber filled nylon filaments and maintain print quality over thousands of hours. Out of material sensors ensure that you’re always printing while a scanning laser on the printhead enables the printer to dynamically adjust the first layers of a print to achieve perfect bed adhesion.

Software

Markforged Eiger Cloud (Other options available at cost)

3D Printer Footprint

584 x 483 x 914 mm (23 x 19 x 36 in)

Weight

46 kg (102 lbs)

Power Requirements

100–240 VAC, 150 W (2 A peak)

Print high-quality parts with Markforged's micro carbon fiber reinforced nylon filaments.

Revolutionary parts are just a form away!

Connect with one of our additive manufacturing experts to Request a Quote, Sample part or Discuss an 3D printing application