We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Markforged Onyx Pro 3D Printer

Product of Interest:

Markforged Onyx Pro 3D Printer

SKU: F-PR-4012-1

The Onyx Pro 3D printer from Markforged provides companies with extreme versatility and functionality. The Onyx Pro 3D printer is ideal for 3D printing tooling - jigs, jaws and fixtures - for a fraction of the price versus traditionally machining these parts from aluminum. Utilizing Markforged's unique continuous Fiberglass reinforcement the Onyx Pro 3D printer can print stronger more ridged parts.

Markforged Onyx Pro 3D Printer

Capable of 3D printing Fiberglass-reinforced parts 10x stronger than ABS — the Onyx Pro leverages the power of Continuous Fiber Reinforcement at an unbeatable price point.

Continuous Fiber, Made Accessible

Print Continuous Fberglass-reinforced parts 10x stronger than ABS — extremely durable and capable of replacing some machined aluminum parts.

Precise and Beautiful Parts

Print precise parts with best-in-class surface finish thanks to Onyx, Markforged’s extremely versatile micro carbon fiber filled nylon material.

Built to Last

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

3D Printing Process

Continuous Fiber Reinforcement (CFR)

Printing Material

Composite Base Filaments, Continuous Fibers

Build Envelope Size

320 mm x 132 mm x 154 mm (12.6 x 5.2 x 6 in)

Onyx

Fiberglass

About the Onyx Pro

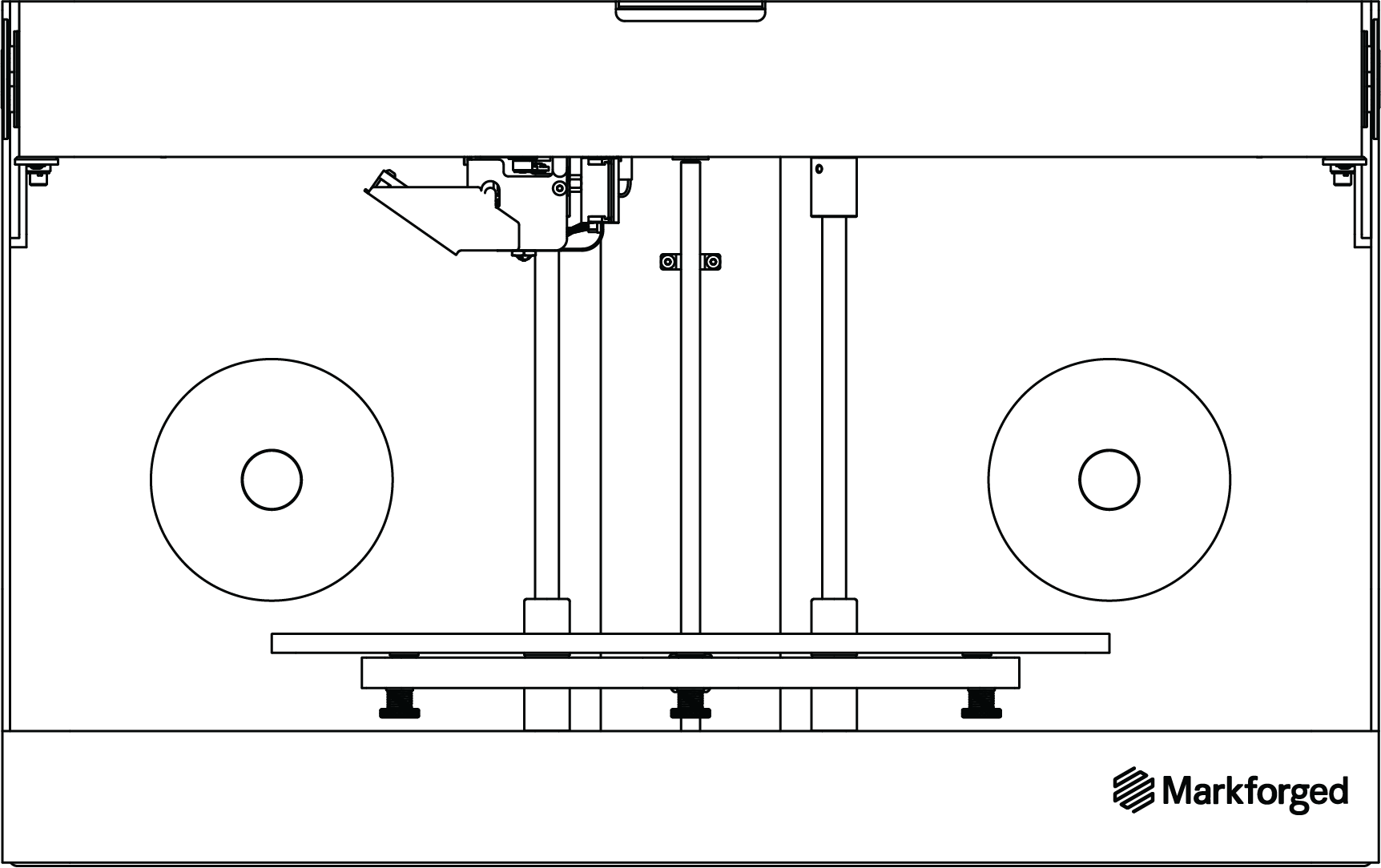

The Onyx Pro is an advanced professional 3D printer – built around the Continuous Fiber Reinforcement (CFR) process to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Onyx Pro to print Onyx — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

In addition to more common FFF features, the Onyx has a 2nd-generation fiber reinforcement system that enables you to lay down continuous Fiberglass into parts. Only Markforged composite printers are capable of printing continuous fiber reinforced parts, which can replaced machined aluminum parts.

Software

Markforged Eiger Cloud (Other options available at cost)

3D Printer Footprint

584 x 330 x 355 mm (23 x 13 x 14 in)

Weight

16 kg (35 lbs)

Power Requirements

100–240 VAC, 150 W (2 A peak)

Leverage the power of Continuous Fiberglass reinforcement to print parts 10x stronger than plastic.

Revolutionary parts are just a form away!

Connect with one of our additive manufacturing experts to Request a Quote, Sample part or Discuss an 3D printing application